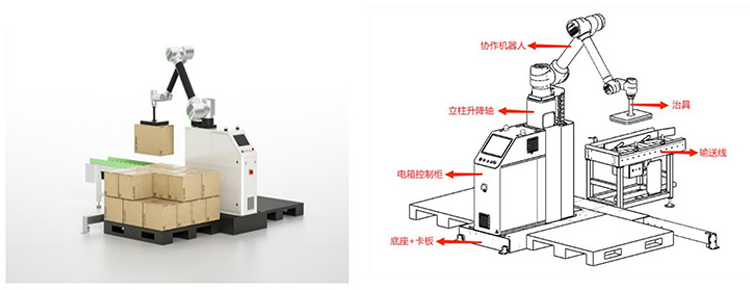

As an innovative equipment in the field of industrial automation, the collaborative palletizer breaks the limitation of "isolated operation" of traditional palletizers. With three core advantages—safe collaboration, intelligent flexibility, and high efficiency & precision—it has become a key equipment in modern production lines. Integrating advanced visual recognition technology, force control sensing system, and flexible mechanical structure, the equipment can work closely with humans without complex safety barriers. When detecting the proximity of personnel, it will automatically decelerate or stop, ensuring operational safety from the source.

In terms of performance, the collaborative palletizer boasts strong adaptability. It can quickly switch between materials of different forms such as cartons, bags, and barrels, with a palletizing weight range of 1-50kg and a maximum stacking height of 2.2 meters. It stably completes 800-1200 palletizing cycles per hour, far exceeding manual efficiency. Meanwhile, the equipment is equipped with an intelligent programming system supporting a graphical user interface, allowing quick setup of palletizing schemes without professional programming knowledge. Combined with automatic deviation correction, anti-toppling detection and other functions, it ensures the palletizing accuracy error is controlled within ±2mm, greatly improving the standardization and stability of warehousing and stacking. In addition, adopting a modular design, the equipment covers only 1/3 of the area of traditional palletizers, enabling flexible integration into existing production lines without large-scale plant renovation, effectively reducing enterprise upgrading costs.

With its flexibility and high adaptability, the collaborative palletizer has been widely applied in various industries such as food and beverage, chemical building materials, pharmaceutical packaging, warehousing and logistics, and e-commerce express delivery, becoming a core solution to solve enterprises' pain points of "difficulty in recruiting workers, low efficiency, and high costs".

As a dedicated player in the industrial automation field, we have always focused on the R&D, production, and service of collaborative robots and intelligent palletizing equipment, committed to providing efficient, flexible, and safe automation solutions for enterprises worldwide. The company has a core R&D team composed of experts in mechanical engineering, electronic information, artificial intelligence and other fields, accumulating more than 50 national patents, and its technical strength is at the leading level in the industry.

Adhering to the product concept of "customer demand-oriented", we provide one-stop full-process services from scheme design, equipment production, installation and commissioning to after-sales maintenance. Tailored palletizing solutions can be customized according to the needs of customers in different industries and with different production capacities, ensuring seamless connection between the equipment and customers' existing production lines. In the production link, we strictly follow the ISO9001 quality management system and select core components of internationally renowned brands to ensure the stability and durability of the equipment. In the after-sales link, a 24-hour rapid response mechanism has been established, with service outlets set up in many places across the country to provide customers with timely technical support and maintenance services, ensuring the continuous and stable operation of production lines.

Over the years, our products have served thousands of enterprises covering food, chemical, pharmaceutical, logistics and other fields. With reliable product quality, professional technical schemes and high-quality after-sales service, we have won wide recognition and a good reputation from customers. In the future, we will continue to deepen technological innovation, promote the development of collaborative palletizing equipment towards a more intelligent, flexible, and energy-saving direction, and help more enterprises achieve automated upgrading, cost reduction and efficiency improvement.

If you are facing problems such as rising labor costs, low palletizing efficiency, and potential operational safety hazards, or want to promote the intelligent upgrading of your production line, please feel free to contact us! Our professional team will provide you with free scheme consultation, on-site survey and equipment demonstration services, and customize exclusive collaborative palletizing solutions according to your actual needs, helping you quickly achieve cost reduction, efficiency improvement, and enhance core competitiveness.

Consultation Hotline: 86-18217549692

Official Email: oliver@boevan.cn

Company Address: No. 6818 Daye Road, Jinhui Town, Fengxian District, Shanghai, China

We look forward to cooperating with you to empower production with intelligent technology and create a new ecosystem of automated and intelligent future industry!