As a key link in the closed loop of manufacturing production, the back-end packaging line serves as the central hub connecting product manufacturing and market circulation. Integrating automated and intelligent technologies, it realizes standardized full-process operations from product offline to finished product warehousing, providing core support for enterprises to reduce costs, improve efficiency, and ensure quality.

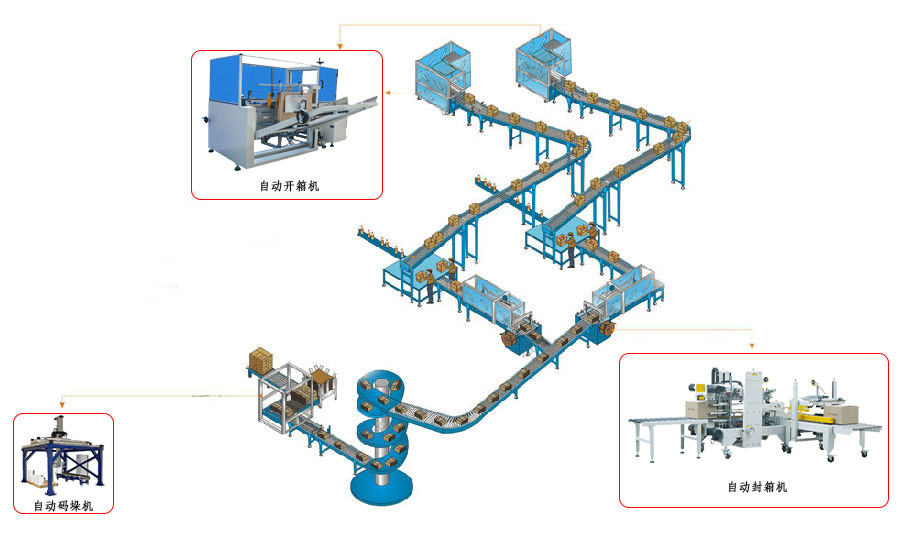

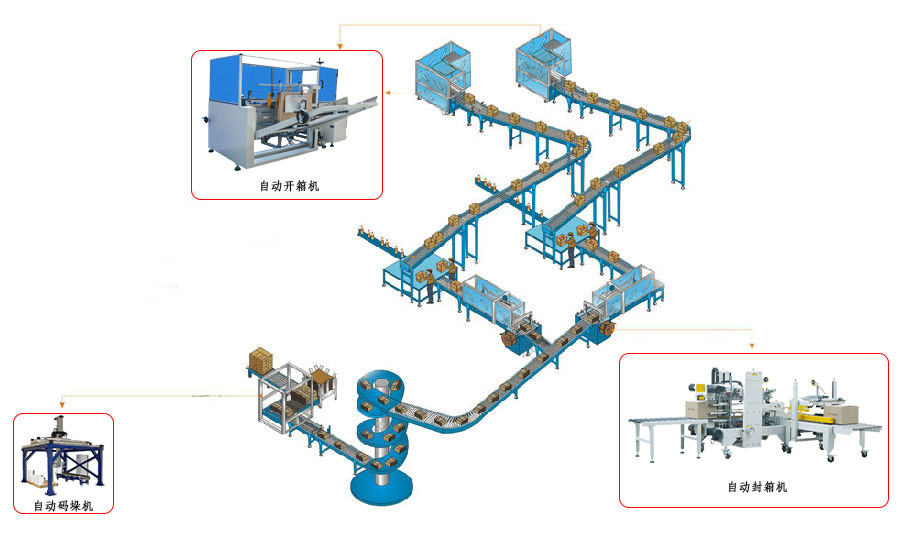

Adhering to the core design philosophy of "precision, efficiency, and flexibility", the production line consists of four core modules. Firstly, the product sorting unit coordinates with conveyor belts and positioning devices to complete orderly arrangement, shunting, and posture correction of products. It adapts to products of different specifications and shapes, solving the pain points of low efficiency and high error rate in manual sorting. Secondly, the packaging execution unit integrates functions such as automatic bagging, carton sealing, strapping, and labeling. It can switch packaging methods according to product needs—from vacuum packaging in the food industry, heat shrink packaging in the daily chemical industry to anti-static packaging in the electronics industry—achieving "one machine for multiple uses". Thirdly, the inspection and traceability unit is equipped with visual inspection, weight verification, and barcode scanning technologies. It real-time detects problems such as packaging damage, missing parts, and label errors, while generating traceable data to meet quality control and compliance requirements. Finally, the palletizing and warehousing unit uses robotic arms or palletizers to complete automatic stacking and stretch film fixing of finished products, and cooperates with AGV trolleys for transportation to warehouses, realizing seamless connection between "packaging, palletizing, and warehousing".

Compared with traditional manual packaging, the automated back-end packaging line has three core advantages. In terms of efficiency, a single production line can process hundreds to thousands of products per hour, with productivity 3-5 times higher than manual operations, and realizes 24/7 continuous operation, significantly shortening the delivery cycle. In terms of quality, through precise mechanical control and intelligent inspection, the packaging qualification rate is stably above 99.9%, avoiding random errors caused by manual operations. In terms of cost, in the long run, it can reduce more than 80% of labor input, lower consumable waste and management costs, and optimize production scheduling through data-driven management to improve overall operational efficiency.

Currently, the back-end packaging line has been widely used in various industries such as food and beverage, pharmaceutical and healthcare, daily chemicals, 3C electronics, and hardware and building materials. To meet the special needs of different industries, customized solutions are available—such as GMP-compliant design for the pharmaceutical industry, fresh-keeping packaging integration for the fresh food industry, and buffer protection adaptation for fragile products. It helps enterprises achieve standardized and intelligent upgrading of packaging processes, laying a solid backend foundation for market competition.