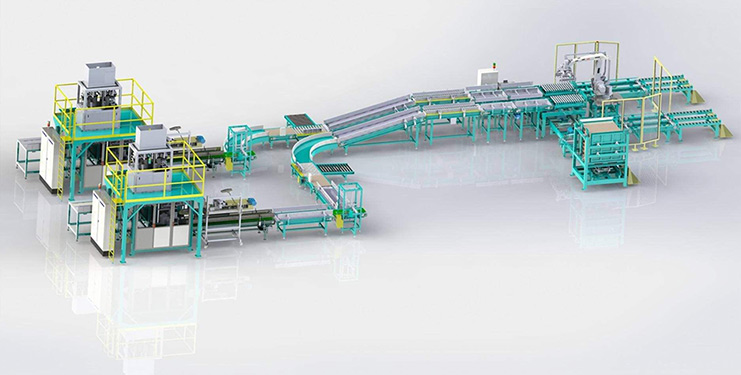

The automatic post-packaging line is an integrated intelligent production system designed for the post-processing stage of finished products. It integrates multiple functional modules such as automatic cartoning, case packing, sealing, coding, weighing, metal detection, palletizing and intelligent conveying. It is mainly used to complete the standardized packaging and finishing of various finished products (including food, medicine, daily chemicals, electronics, hardware, etc.) after the production process, realizing the seamless connection from single product to finished package, and then to palletized storage. Compared with the traditional manual or semi-automatic post-packaging mode, the automatic post-packaging line not only greatly improves the packaging efficiency and consistency, but also effectively ensures the packaging quality and safety, reduces labor intensity and human errors, and provides reliable support for enterprises to realize standardized production, brand upgrading and cost control. It has become an indispensable core equipment in the modern production lines of many industries.

1. Core Advantages

•Integrated Efficient Operation: The line integrates multiple post-packaging processes such as cartoning, case packing, sealing, coding and palletizing, realizing one-stop continuous operation without manual transfer between processes. The production capacity can reach 300-2000 pieces/hour (adjustable according to product specifications), which is 5-8 times that of manual operation, greatly shortening the production cycle.

•Stable Quality and Safety Assurance: Adopting high-precision servo control and intelligent detection technology, it can accurately complete actions such as product positioning, material folding and sealing, ensuring the consistency of packaging appearance and sealing tightness. Equipped with weighing detection, metal detection, missing parts detection and other systems, it can automatically reject unqualified products, effectively avoiding unqualified packaging from flowing into the market and ensuring product safety and brand reputation.

•Flexible Adaptability, Wide Application: It supports quick switching of packaging specifications and processes by modifying parameters on the touch screen, which can adapt to the packaging needs of different sizes, shapes and materials of products. It is widely applicable to food (snacks, dairy products, condiments), medicine (tablets, capsules, injections), daily chemicals (cosmetics, toiletries), electronics (small components, finished products) and other industries.

•Cost Reduction and Efficiency Improvement, Safe and Reliable: A single automatic post-packaging line can replace 8-12 manual workers, significantly reducing labor costs, management costs and labor-related safety risks. The core components adopt international well-known brands, with a mean time between failures (MTBF) of more than 10,000 hours. The whole line is equipped with complete safety protection devices (safety gratings, emergency stop buttons, protective covers, etc.), complying with international safety standards to ensure the safety of operators and equipment.

•Intelligent Management and Traceability: Equipped with an intelligent central control system, it can realize real-time monitoring of production data (output, qualified rate, fault information, etc.), automatic data statistics and report generation. The coding system can print production date, batch number, traceability code and other information, realizing full-process traceability of products and facilitating enterprise quality management and market supervision.

2. Core Components and Working Process

The automatic post-packaging line is composed of multiple functional modules with close coordination, and the working process is scientific and efficient, covering the whole post-packaging link of finished products:

•Product Conveying Module: Composed of belt conveyors, roller conveyors and other equipment, it is responsible for stably conveying the finished products from the front-end production line to each post-packaging process station, ensuring the continuity of the production line.

•Cartoning/Case Packing Module: According to the product type, it completes automatic cartoning (putting single products into cartons) or case packing (putting cartoned products or single bulk products into turnover cases). It is equipped with automatic material feeding, folding and forming mechanisms to ensure accurate and efficient packaging.

•Sealing and Coding Module: Realizes automatic sealing of cartons/cases (adopting adhesive tape or hot melt adhesive sealing mode) and automatic coding of information such as production date, batch number and traceability code. The coding is clear and wear-resistant, meeting the national food and drug packaging standards.

•Quality Detection Module: Integrates weighing detector, metal detector, missing parts detector, etc. It can automatically detect whether the product weight is qualified, whether there are metal impurities mixed in, and whether the packaging is missing parts (such as instructions, accessories). Unqualified products will be automatically pushed to the unqualified product area.

•Palletizing and Storage Module: The qualified packaged products are conveyed to the palletizing station, and the palletizing robot automatically grabs and stacks the products on the pallet according to the preset program. After the palletizing is completed, the pallet is conveyed to the warehouse by the pallet conveyor, realizing the connection between post-packaging and warehousing.

•Central Control System: The "brain" of the whole line, composed of PLC controller, touch screen and industrial computer. It is responsible for coordinating the action sequence of each module, collecting and processing production data, issuing operation instructions, and supporting functions such as remote monitoring and fault alarm.

3. Typical Application Scenarios

The automatic post-packaging line is widely used in various industries that require standardized post-processing of finished products, and typical application scenarios include:

•Food Industry: Automatic cartoning, case packing, sealing and coding of snacks (potato chips, biscuits), dairy products (yogurt, milk powder), condiments (soy sauce, vinegar, seasonings), frozen food, etc.;

•Pharmaceutical Industry: Automatic packaging of tablets, capsules, injections, medical devices and other products, including cartoning, inserting instructions, sealing, coding, and metal detection to ensure compliance with GMP standards;

•Daily Chemical Industry: Automatic case packing and palletizing of cosmetics (skin care products, cosmetics), toiletries (shampoo, soap), paper products (tissue, paper towels) and other finished products;

•Electronics Industry: Automatic packaging of small electronic components (resistors, capacitors), finished electronic products (mobile phones, headphones) and other products, with anti-static and anti-collision protection functions;

•Hardware and Daily Necessities Industry: Automatic case packing and palletizing of small hardware (screws, nuts), plastic products, daily necessities and other bulk products.

Boevan Technology Co., Ltd. is a high-tech enterprise specializing in the R&D, production, sales and service of intelligent packaging equipment. It focuses on the R&D and promotion of automatic post-packaging lines, intelligent cartoning machines, case packing machines and integrated packaging automation solutions. Since its establishment, our company has always adhered to the business philosophy of "taking technological innovation as the core and customer needs as the guide", and is committed to providing efficient, stable and personalized automatic post-packaging solutions for customers in various industries to help enterprises realize industrial upgrading, improve product quality and enhance market competitiveness.

Our company has a professional R&D team composed of senior engineers in the fields of mechanical design, electrical control, software programming and packaging technology, with strong independent R&D and customized design capabilities. We can tailor exclusive automatic post-packaging lines and supporting equipment according to the customer's product characteristics, packaging requirements, production capacity and workshop layout. The company's production base is equipped with advanced processing equipment and strict quality control system. From the procurement of core components to product assembly, commissioning and testing, every link strictly follows the ISO9001 quality management system standard to ensure the stability and reliability of product quality.

In terms of service, our company has established a complete pre-sales, in-sales and after-sales integrated service system: pre-sales provides free on-site survey, demand analysis, scheme design and technical consultation; in-sales arranges a professional technical team to follow up the equipment installation, commissioning and operator training throughout the process to ensure the rapid commissioning of the equipment; after-sales provides a 24-hour technical support hotline, which responds quickly after receiving a fault notification. It arrives at the scene to solve problems within 24 hours in the province and 48 hours outside the province. At the same time, it regularly provides equipment inspection and maintenance services to ensure the long-term stable operation of the equipment.

With high-quality products, professional technology and thoughtful services, our company's automatic palletizing lines and automation solutions have successfully served thousands of enterprises across the country, covering food, chemical, grain and oil, feed, pharmaceutical and other industries, winning wide recognition and good reputation from customers. In the future, our company will continue to deepen the field of intelligent equipment, continuously iterate technologies and products, provide customers with more intelligent and efficient production solutions, and help enterprises achieve higher-quality development.

If you have any questions about our company's automatic post-packaging line and integrated packaging automation solutions, or need to customize an exclusive post-packaging production solution, please feel free to contact us at any time! We will arrange professional technical consultants to provide you with one-on-one consulting services, answer your questions in detail, and provide you with accurate scheme design and quotation.

Contact Information

Consultation Hotline: 86-18217549692

Official Email: oliver@boevan.cn

Company Address: No. 6818 Daye Road, Jinhui Town, Fengxian District, Shanghai, China

BoevanTechnology Co., Ltd. looks forward to cooperating with you to build a new future of intelligent post-packaging!