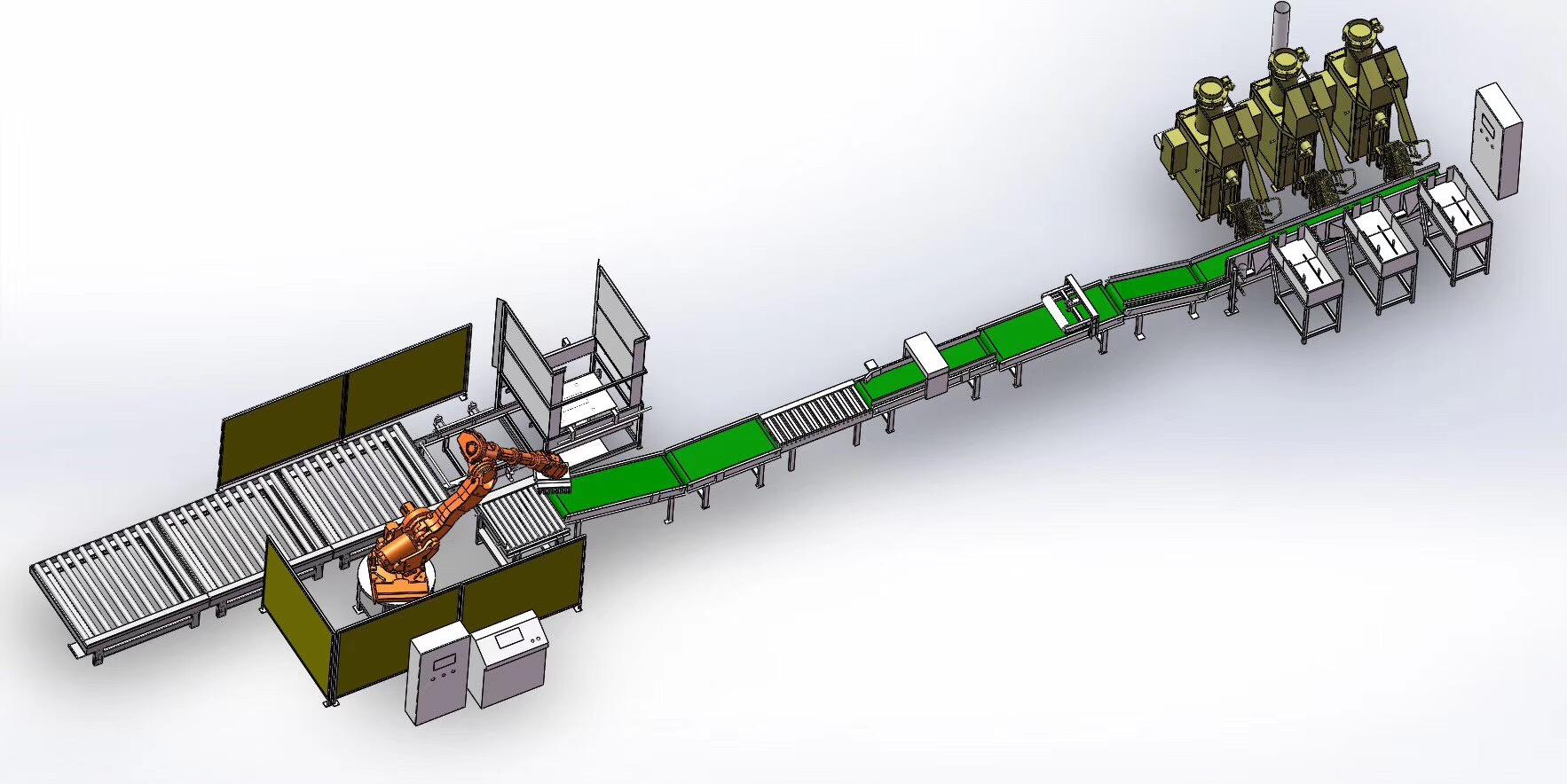

The automatic palletizing line is an intelligent end-of-packaging solution integrating multiple fields such as machinery, electrical engineering, pneumatics, and software control. It is mainly used to complete a series of processes including automatic sorting, positioning, grabbing, palletizing and pallet conveying of various materials (such as bagged, boxed, barreled, bottled, etc.). Compared with traditional manual palletizing or semi-automatic palletizing modes, the automatic palletizing line, relying on its high degree of automation and intelligence, completely liberates human resources, greatly improves the efficiency and stability of palletizing operations, and effectively reduces manual operation errors, material loss and safety production risks. It has been widely used in many industries such as food and beverage, grain and oil, chemical building materials, feed breeding, pharmaceutical and daily chemicals, warehousing and logistics.

1. Core Advantages

•Efficient and Intelligent, Enhancing Production Capacity: Adopting high-precision servo control system and advanced visual positioning technology, it can realize 24/7 continuous operation. The maximum palletizing speed can reach 1200 cycles per hour (adjustable according to material type), which is far higher than the manual efficiency of 300-500 cycles per hour. It has the functions of intelligently identifying material specifications and automatically switching palletizing programs, adapting to the flexible production needs of multi-variety and multi-specification materials without frequent manual debugging.

•Stable and Reliable, Reducing Losses: The gripping accuracy of the robotic arm is up to ±1mm, and the palletizing is highly neat, which can effectively avoid material dumping and damage caused by fatigue and irregular operation in manual palletizing. The core components of the equipment are of well-known brands, with low failure rate. The Mean Time Between Failures (MTBF) exceeds 8000 hours, greatly reducing downtime maintenance costs.

•Cost-saving, Safe and Controllable: A single automatic palletizing line can replace 6-8 manual workers, saving hundreds of thousands of yuan in labor costs annually. The whole process is automated, without manual direct contact with heavy objects, avoiding safety accidents such as high-altitude falls and heavy object crushing. It is equipped with complete safety protection devices (such as safety light curtains, emergency stop buttons, protective fences) and complies with ISO safety standards to ensure the safety of the operating environment.

•Easy to Operate and Integrate: Adopting a humanized touch screen operation interface and graphical programming, it can be quickly mastered without professional programming knowledge. It supports seamless docking with upstream production lines (such as packaging machines, conveyors) and downstream warehousing systems (such as AGV trolleys, automated warehouses), realizing the full-process automated closed-loop management from production to warehousing. It can be customized and designed according to the customer's workshop layout, material characteristics and palletizing requirements.

2. Core Components

The automatic palletizing line is composed of multiple coordinated modules, each with a clear division of labor to ensure the smooth and efficient operation of the overall work:

•Conveyor System: Including material conveyors, pallet conveyors, finished product palletizing conveyors, etc. It is responsible for stably conveying materials to be palletized to the grabbing station, conveying empty pallets to the starting position of palletizing, and conveying finished palletized pallets to the designated area.

•Palletizing Robot/Robotic Arm: The core executive component. Different gripping fixtures (such as vacuum suction cups, grippers, clamping jaws, fork claws, etc.) are equipped according to the material type to realize stable gripping and precise palletizing of materials of different shapes.

•Control System: Composed of PLC controller, touch screen, servo driver, etc., it is the "brain" of the palletizing line. It is responsible for coordinating the action sequence of each module, receiving sensor signals, executing palletizing programs, and supporting functions such as parameter setting, fault alarm and production data statistics.

•Safety Protection System: Including protective fences, safety light curtains, emergency stop buttons, warning lights, etc. When a person or foreign object enters the dangerous area, the equipment stops immediately to ensure the safety of personnel and equipment.

•Auxiliary System: Configured according to customer needs, such as automatic pallet feeder, pallet stretch film wrapping machine (for fixing finished palletizing), material sorting and positioning device, waste recycling device, etc.

3. Application Scenarios

The automatic palletizing line is suitable for various material forms and industry needs. Typical application scenarios include:

•Food and Beverage Industry: Bagged milk powder, boxed beverages, bottled water, cans, frozen food boxes, etc.;

•Grain, Oil and Chemical Industry: Bagged flour, rice, cement, chemical fertilizers, chemical raw materials, barreled lubricating oil, coatings, etc.;

•Feed Breeding Industry: Bagged feed, premix, pet food, etc.;

•Pharmaceutical and Daily Chemical Industry: Boxed medicines, bottled cosmetics, bagged washing powder, etc.;

•Warehousing and Logistics Industry: Centralized palletizing and warehousing transfer of various finished product boxes and turnover boxes.

Boevan Technology Co., Ltd. is a high-tech enterprise specializing in the R&D, production, sales and service of intelligent equipment. It focuses on the R&D and promotion of automatic palletizing equipment, intelligent conveying systems and warehousing automation solutions. Since its establishment, our company has always adhered to the business philosophy of "taking technological innovation as the core and customer needs as the guide", and is committed to providing efficient, stable and personalized automatic production solutions for customers in various industries to help enterprises realize industrial upgrading, reduce costs and increase efficiency.

Our company has a R&D team composed of senior engineers in the fields of mechanical design, electrical control, software programming, etc., with strong independent R&D and customized design capabilities. We can tailor suitable automatic palletizing lines and supporting automatic systems according to the specific needs of customers such as workshop layout, material characteristics and production rhythm. The company's production base is equipped with advanced processing equipment and strict quality control system. From the procurement of core components to product assembly and commissioning, every link follows the ISO9001 quality management system standard to ensure stable and reliable product quality.

In terms of service, our company has established a complete pre-sales, in-sales and after-sales integrated service system: pre-sales provides free on-site survey, demand analysis, scheme design and technical consultation; in-sales arranges a professional technical team to follow up the equipment installation, commissioning and operator training throughout the process to ensure the rapid commissioning of the equipment; after-sales provides a 24-hour technical support hotline, which responds quickly after receiving a fault notification. It arrives at the scene to solve problems within 24 hours in the province and 48 hours outside the province. At the same time, it regularly provides equipment inspection and maintenance services to ensure the long-term stable operation of the equipment.

With high-quality products, professional technology and thoughtful services, our company's automatic palletizing lines and automation solutions have successfully served thousands of enterprises across the country, covering food, chemical, grain and oil, feed, pharmaceutical and other industries, winning wide recognition and good reputation from customers. In the future, our company will continue to deepen the field of intelligent equipment, continuously iterate technologies and products, provide customers with more intelligent and efficient production solutions, and help enterprises achieve higher-quality development.

If you have any questions about our company's automatic palletizing line and automation solutions, or need to customize an exclusive automatic production solution, please feel free to contact us at any time! We will arrange professional technical consultants to provide you with one-on-one consulting services, answer your questions in detail, and provide you with accurate scheme design and quotation.

Contact Information

Consultation Hotline: 86-18217549692

Official Email: oliver@boevan.cn

Company Address: No. 6818 Daye Road, Jinhui Town, Fengxian District, Shanghai, China

Boevan Technology Co., Ltd. looks forward to cooperating with you to build a new future of intelligent production!