Traditional carton sealers struggle with inconsistent carton sizes, uneven surfaces, or lightweight cartons, leading to skewed sealing, tape breakage, or carton collapse. This intelligent sealer is equipped with AI Dynamic Sensing System and Dual-Servo Tape Feeding Mechanism, which can automatically detect carton height (100-600mm), width (150-500mm), and surface flatness in 0.1 seconds. It adjusts sealing pressure and tape tension in real time, achieving smooth and firm sealing for thin-walled cartons, corrugated cartons, and even slightly deformed cartons. The sealing precision error is ≤±0.5mm, and the tape adhesion rate reaches 99.9%, completely solving the problem of substandard sealing caused by carton inconsistency.

Targeting large-scale packaging scenarios such as e-commerce and logistics, the equipment adopts a High-Speed Linkage Transmission System optimized through bionics. The maximum sealing speed reaches 60 cartons per minute, which is 3 times that of ordinary sealers (20 cartons/minute) and 12 times that of manual operation (5 cartons/minute). At the same time, it innovatively uses a frequency conversion energy-saving motor and a tape preheating and bonding technology, reducing power consumption by 30% compared with traditional models (only 0.8kW/h) and saving 15% of tape usage by minimizing redundant tape overlap. For enterprises with a daily output of 50,000 cartons, it can save more than 300,000 yuan in energy and material costs annually.

To meet the diverse needs of different industries, the sealer supports automatic switching between tape sealing and hot melt adhesive sealing—tape sealing is suitable for general logistics scenarios (fast and low-cost), while hot melt adhesive sealing is for high-strength packaging needs (such as heavy goods, long-distance transportation) with a bonding strength 2.5 times that of tape. It is also integrated with Intelligent Fault Prediction and Alarm System: through real-time monitoring of key components such as tape rolls, motors, and sensors, it can predict potential failures (e.g., low tape stock, abnormal pressure) 10 minutes in advance and send alerts via sound, light, and mobile APP. The 3-year failure rate is only 0.2%, and the average time between failures (MTBF) exceeds 8,000 hours, supporting 24/7 uninterrupted operation.

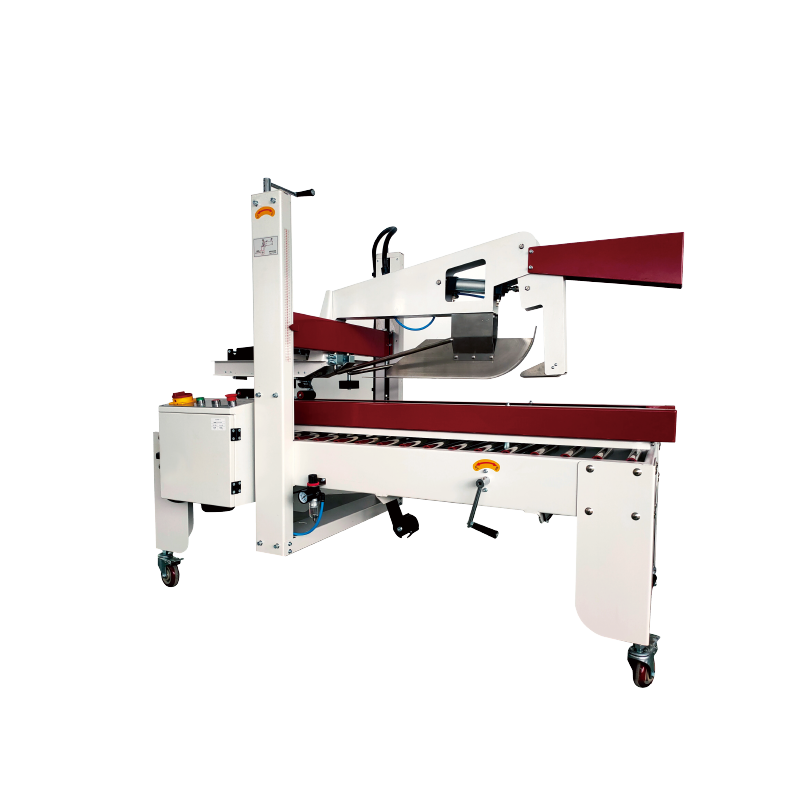

For food, pharmaceutical, and medical device industries with strict hygiene requirements, the sealer adopts 304 food-grade stainless steel body, IP68 waterproof and dustproof coating, and a detachable structure without dead corners. It can be easily cleaned and disinfected, complying with FDA and GMP standards. In terms of system integration, it supports seamless connection with upstream carton erectors, downstream labeling machines, and WMS/ERP systems. It can automatically synchronize order information, record sealing data (e.g., time, quantity, operator), and realize full-process traceability. The compact design (L1800×W850×H1600mm) allows it to be installed in narrow spaces, and it can be quickly integrated into existing packaging lines without major modifications.