Traditional carton erectors have strict requirements for carton quality, with wrinkled, soft, or irregular cartons often causing jams and damage. Equipped with 90° Active Forming Technology and Multi-group Servo Suction Cup System, this intelligent carton erector not only effortlessly handles wrinkled and slightly damaged "rough cartons" with a forming rate of 99.8% but also adapts to non-standard cartons such as flip-top, windowed, and irregular bottom supports through customized molds and programmable motion trajectories. The processing efficiency jumps from 15-20 cartons per hour (manual operation) to 120 cartons per hour, completely solving the efficiency pain points of special packaging scenarios.

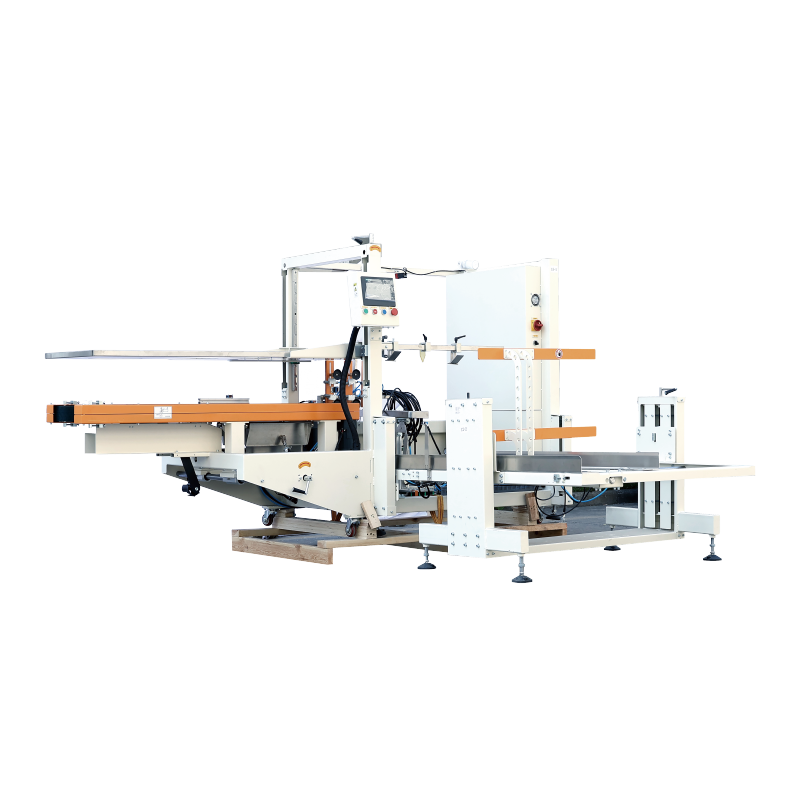

Targeting multi-SKU production needs, the equipment innovatively adopts a Parametric Intelligent Adjustment System. Carton size switching can be completed via a touch screen in only 3-5 minutes, far exceeding the 30-minute changeover cycle of traditional equipment. Meanwhile, the machine body is made of lightweight high-strength materials, weighing only 280kg, with heavy-duty universal wheels and brake locking devices at the bottom. It can be easily pushed by a single person and flexibly moved among 3+ packaging stations, perfectly adapting to the production status of small and medium-sized enterprises (SMEs) with limited space and variable orders.

As an Industry 4.0-compatible device, this machine is deeply integrated with IoT and AI Vision Inspection System:

•Through the interconnection between PLC controller and enterprise ERP system, it real-time uploads data such as carton erecting quantity, consumable consumption, and equipment status. Managers can remotely monitor via mobile phones/computers, predict faults, and replenish consumables in a timely manner, increasing equipment utilization by 15%.

•The high-definition vision module real-time detects carton forming accuracy and barcode information, automatically rejecting unqualified products. The defect rate is controlled below 0.1%, reducing inspection costs by 40% compared with manual inspection.

Tailored solutions for special industry needs:

•For fresh cold chain scenarios: Adopts low-temperature dedicated motors and anti-freeze sensors, maintaining stable operation at -10℃. The hot melt adhesive system heats up rapidly in 10 seconds without compromising sealing strength.

•For humid environments (e.g., aquatic product and fruit/vegetable processing): Equipped with 304 stainless steel body and IP67 waterproof packaging, improving rust resistance by 5 times with a 3-year failure rate of only 0.3%.

Key components undergo 1000-hour aging tests, achieving a 99% integrity rate after 3 years of continuous operation. It supports 24/7 uninterrupted work, and tape replacement does not require production interruption.

•Efficiency Surge: Medium models achieve 15-25 cartons/minute, while large models reach up to 40 cartons/minute—8-10 times higher than manual efficiency, increasing single-line production capacity by 30%.

•Cost Optimization: Reduces labor demand from 3 workers/line to 1 worker/line, saving over 1.2 million RMB in annual labor costs. Lowers carton damage rate from 3.5% to below 1%, cutting consumable costs by 10%.

•Precision Control: Forming dimension error ≤ ±1mm, with flat and bubble-free tape sealing, complying with ISTA transportation test standards to ensure subsequent packaging and transportation safety.

•Easy Operation & Maintenance: Humanized touch interface + modular design allows ordinary employees to master operation in 1 hour. Daily maintenance time is shortened from 45 minutes to 15 minutes.

Whether for mass standard carton erecting in e-commerce logistics, hygienic packaging in food and pharmaceutical industries, low-temperature operations in fresh cold chains, irregular carton forming in the gift industry, or flexible station switching in SMEs, this intelligent carton erector can serve as the core efficiency-enhancing equipment for packaging lines through customized configurations and strong environmental adaptability. From e-commerce warehouses with 30,000 daily orders to small food processing plants, it has helped thousands of enterprises achieve packaging automation upgrades, with the shortest investment payback period of only 1.5 years.