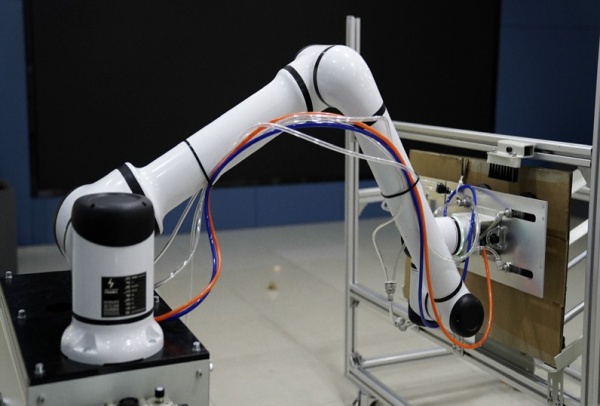

The Robotic Opening, Loading and Sealing Machine is a cutting-edge intelligent packaging equipment integrated with robotic technology, automatic control and precision mechanical transmission. It realizes the full-process automated operation of carton unpacking, product loading and carton sealing through high-precision robotic arms and intelligent control systems. Compared with traditional semi-automatic equipment, this machine has more outstanding flexibility, precision and efficiency, and can adapt to the complex and diverse packaging needs of modern industrial production, effectively promoting the transformation of the packaging link from labor-intensive to technology-intensive.

In terms of core performance, the robotic opening, loading and sealing machine has four core advantages: First, high-precision robotic operation. Equipped with multi-axis high-precision robotic arms, it can achieve millimeter-level positioning accuracy for product loading. It is applicable to products of various shapes and sizes, and can complete flexible clamping and placement without damaging the products, which is especially suitable for packaging of fragile and precision products. Second, intelligent adaptive capability. It is equipped with advanced machine vision recognition system and AI algorithm, which can automatically identify product specifications, carton positions and packaging defects. It can realize automatic parameter adjustment and rapid switching between different production tasks without manual intervention, greatly improving production flexibility. Third, efficient and stable operation. The robotic system can work continuously for 24 hours without fatigue, with a packaging efficiency 8-12 times that of manual operation. The stable mechanical structure and mature control algorithm ensure the consistency of packaging quality, effectively avoiding problems such as uneven sealing and wrong loading caused by manual operation. Fourth, safe and humanized design. It is equipped with multiple safety protection devices such as safety light curtains and emergency stop buttons to ensure the safety of operators. At the same time, it adopts a modular design, which is convenient for later maintenance and parts replacement. The man-machine interaction interface is simple and intuitive, and operators can master the operation skills after simple training.

In addition, the machine supports seamless connection with the enterprise's MES production management system, which can realize real-time monitoring of packaging data, production scheduling and fault early warning. It provides data support for the enterprise's intelligent production management, helping enterprises to improve production management efficiency and realize lean production.

With its unique advantages of intelligence, precision and flexibility, the robotic opening, loading and sealing machine has been widely used in multiple high-end and demanding industries. It has become an important supporting equipment for enterprises to improve product quality, enhance production efficiency and build core competitiveness. The main application fields are as follows:

(I) Precision Electronics Industry

The precision electronics industry has extremely high requirements for product packaging, such as mobile phone chips, precision sensors, electronic components and other products, which are afraid of collision, static electricity and pollution. The robotic opening, loading and sealing machine is equipped with anti-static devices and soft clamping fixtures, which can realize gentle and precise loading of precision electronic products. At the same time, the closed packaging environment can effectively prevent dust and other pollutants from entering, ensuring the quality of electronic products during transportation and storage. It is widely used in the packaging lines of well-known electronic enterprises such as consumer electronics, automotive electronics and industrial electronics.

(II) Pharmaceutical and Biomedical Industry

The pharmaceutical and biomedical industry has strict requirements on the hygiene, accuracy and traceability of packaging. The robotic opening, loading and sealing machine adopts stainless steel materials that meet GMP standards, and the surface is smooth and easy to clean, avoiding cross-contamination. The high-precision robotic arm can accurately complete the loading of medicines, medical devices and biological reagents, ensuring the consistency of packaging dosage and placement. At the same time, the machine can record the packaging data in real time and realize the traceability of the whole process of packaging, which helps enterprises to comply with the strict supervision requirements of the pharmaceutical industry. It is widely used in the packaging of oral preparations, injections, medical catheters and other products.

(III) High-End Food and Beverage Industry

For high-end food and beverage products such as imported snacks, premium wines, and fresh and frozen foods, the requirements for packaging appearance and freshness preservation are relatively high. The robotic opening, loading and sealing machine can realize the gentle loading of food and beverage products, avoiding the damage of packaging boxes and products. The airtight sealing technology can effectively isolate air and moisture, ensuring the freshness of products. At the same time, the machine can adapt to the packaging of various special-shaped boxes and gift boxes, improving the appearance quality of products. It is widely used in the packaging lines of high-end food and beverage enterprises, helping enterprises to enhance the added value of products.

(IV) Automobile Parts Industry

Automobile parts have various types, different sizes and heavy weights, which put forward high requirements for the load capacity and stability of packaging equipment. The robotic opening, loading and sealing machine is equipped with high-load robotic arms, which can easily complete the loading of auto parts such as engines, transmissions and brake systems. The stable clamping and placement ensure that the parts are not damaged during packaging. At the same time, the machine can adapt to the packaging of large and heavy cartons, and the sealed packaging can effectively prevent the parts from rusting and being contaminated during transportation. It is an important equipment in the intelligent packaging workshop of automobile parts enterprises.

(V) New Energy Industry

New energy products such as lithium-ion batteries and photovoltaic modules have strict requirements on packaging safety and precision. The robotic opening, loading and sealing machine can realize the safe and precise loading of new energy products through special fixtures and anti-static design. It avoids short circuits and damage caused by static electricity and collision during the packaging process. The sealed packaging can effectively isolate the external environment and ensure the safety and performance stability of new energy products during transportation and storage. It is widely used in the packaging links of new energy enterprises such as power battery manufacturers and photovoltaic module manufacturers.

As a professional enterprise focusing on the R&D, production and sales of intelligent robotic packaging equipment, we have always adhered to the development concept of "technology leading, customer-centric" and have deep technical accumulation and rich industry experience in the field of robotic packaging. The company's core R&D team is composed of senior engineers in robotics, automatic control, machine vision and other fields, who have long been engaged in the research of intelligent packaging technology and have strong independent innovation capabilities.

In the production process, we have established a strict quality management system covering raw material procurement, parts processing, equipment assembly and factory inspection. We select world-class core components such as robotic arms and sensors to ensure the stability and reliability of each equipment. At the same time, the company has a modern production base and advanced production and processing equipment, which can realize the large-scale production of robotic opening, loading and sealing machines and meet the growing market demand.

We are committed to providing customers with one-stop intelligent packaging solutions. Our service system covers the entire life cycle of the product: pre-sales, professional technical consultants conduct on-site surveys according to the customer's production site, product characteristics and production needs, and customize exclusive packaging solutions for customers; during sales, we arrange professional installation and commissioning teams to complete equipment installation, debugging and operator training to ensure that the equipment is quickly put into production; after-sales, we have a professional after-sales service team and a sound spare parts supply system, providing 24-hour technical support and on-site maintenance services. We regularly conduct return visits to customers to understand the equipment operation status and provide technical optimization suggestions.

Up to now, our robotic opening, loading and sealing machines have been sold to more than 20 provinces, municipalities directly under the Central Government and autonomous regions in China, and have been exported to Southeast Asia, Europe and other regions. We have served hundreds of enterprises in electronics, pharmaceuticals, automobiles and other industries, winning wide recognition and trust from customers. In the future, we will continue to increase investment in R&D, keep up with the development trend of global intelligent manufacturing, and launch more high-performance intelligent robotic packaging equipment to help more enterprises realize industrial upgrading and improve core competitiveness.

If you have needs related to robotic opening, loading and sealing machines, or want to know more about intelligent packaging solutions, please feel free to contact us. Our professional team will provide you with one-on-one detailed consultation services, answer all your questions, and customize the most suitable intelligent packaging solution for you according to your actual needs.

Consultation Hotline: 86-18217549692

Official Email: oliver@boevan.cn

Company Address: No. 6818 Daye Road, Jinhui Town, Fengxian District, Shanghai, China

BoevanTechnology Co., Ltd. looks forward to cooperating with you to build a new future of intelligent post-packaging!