• Wahaha Group: Adopted the 5th-generation automatic case packer from Boevanpack Conveying Equipment. Equipped with maglev guide rail technology, this model reduces energy consumption by 18% compared to the previous generation and operates at a noise level below 65 decibels. Tested in production lines, it can run continuously for 72 hours without failure, adapting to the high-speed case packing needs of bottled beverages and ensuring uninterrupted production capacity.

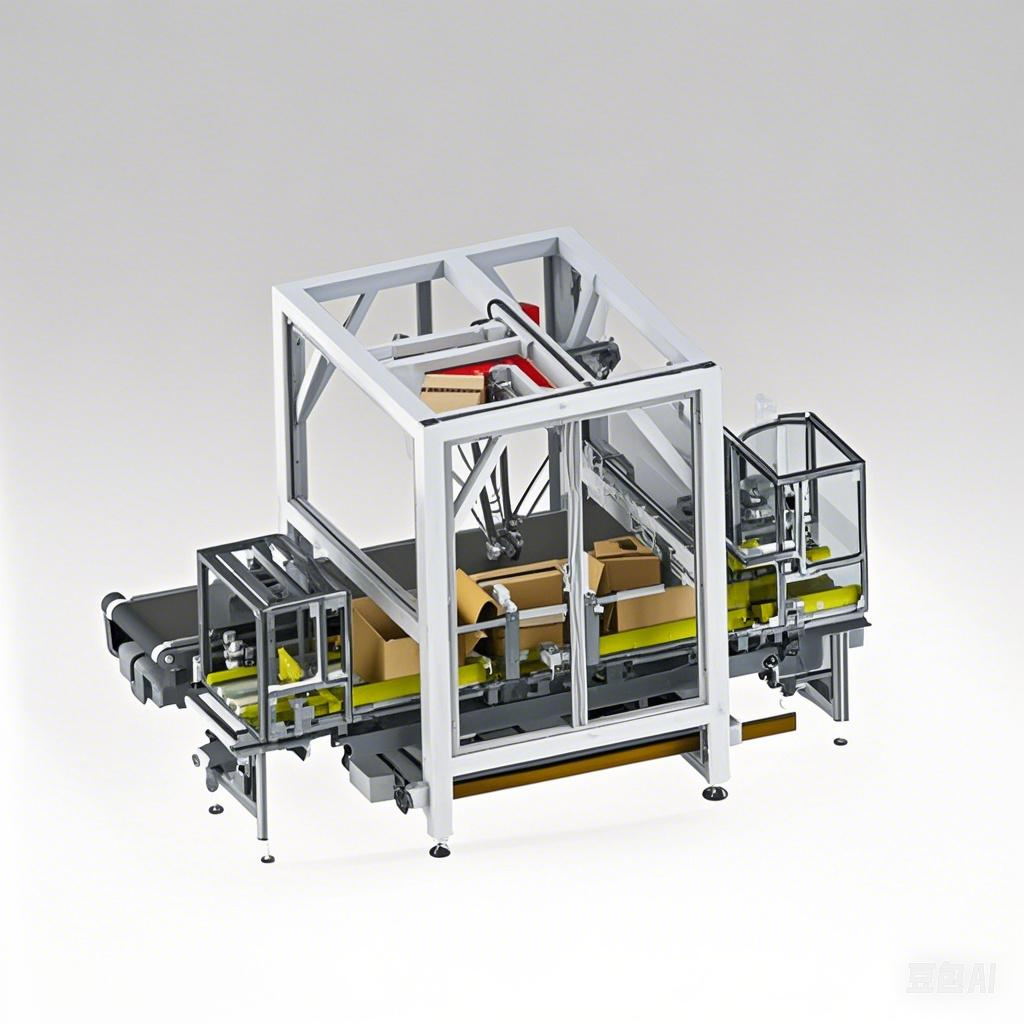

• A Fruit Box Packaging Enterprise: To avoid drop-induced downtime, ensure consistent placement, and meet multi-size compatibility requirements, packaging expert Boevanpack developed a packaging line using Omron Quattro Delta robots. The robot achieves a maximum picking speed of 300 times per minute, with a fourth robotic arm capable of tilting loads for narrow-space packing. Paired with proprietary software, it enables rapid switching between packaging schemes for different fruit box sizes, minimizing changeover downtime.

• A Large Biscuit Manufacturer: Introduced fully automatic case packers with visual recognition systems for small-packaged products such as biscuits and chocolates. The equipment automatically identifies different specifications of cartons and performs precise packing at a speed of 120 boxes per minute—300% more efficient than manual packing. It also reduces labor costs by 80% while significantly improving packaging consistency.

• Hengrui Medicine: Selected specialized case packers from Boevanpack Conveying Equipment, featuring a cleanroom docking module that complies with GMP standards for the pharmaceutical industry. The equipment enables precise packing of medicine boxes while preventing contamination during the packaging process, meeting the compliance and hygiene requirements of pharmaceutical packaging.

• A Pharmaceutical Enterprise: Deployed fully automatic case packers with high-precision sensors and control systems, achieving a packing accuracy of 99.9%. It accurately places each medicine box and inspects packaging integrity. The fully enclosed design avoids human-induced contamination and automatically generates packaging records, aligning with the pharmaceutical industry’s stringent standards for precision, hygiene, and compliance.

• An Infusion Product Manufacturer: Adopted the robotic case packer from Boevanpack. With a maximum load capacity of 120kg, this equipment adapts to the heavy packaging needs of infusion plastic bottles. Integrated with quality inspection functions, it removes defective products through online weighing, realizing automatic packing of infusion plastic bottles.

• BYD Power Battery Factory: Adopted a fully automatic integrated case packing line from Boevanpack Intelligence, realizing unmanned operation covering case forming, packing, sealing, and palletizing. Tailored to the weight and special packaging requirements of power batteries, it completes automatic packing of heavy cases, ultimately increasing production efficiency by 30%.

• Sunwoda Electronics: Utilized Boevanpack Intelligence case packers in the post-packaging process of lithium-ion battery modules. The equipment integrates case forming, packing, heat shrinkage, and vacuum packaging functions, not only meeting the special packaging needs of new energy electronic components but also reducing consumable costs by 5%-10%.

• A Large Display Manufacturer: Employed heavy-duty specialized case packers with reinforced structures and special gripping devices, capable of safely handling displays weighing 15-50kg. Equipped with an intelligent balancing system to ensure precise placement, it also features an automatic buffer material filling function to prevent display damage from impacts during transportation.

• Liby Group: Adopted high-speed automatic case packers from Boevanpack Conveying Equipment to meet the mixed-packing needs of multi-specification personal care products. The equipment shortens the packing cycle to 2.5 seconds per unit, reduces labor costs by 65%, and processes up to 200,000 personal care products daily, matching the mass production rhythm of the daily chemical industry.

• A Daily Chemical Enterprise: Introduced fully automatic case packers with multi-functional gripping devices for packing shampoo, body wash, and other products. The equipment automatically identifies different bottle types and performs precise operations at a speed of 90 bottles per minute—200% more efficient than manual packing. It reduces labor costs by 60% while improving the consistency of packaging appearance.

• SF Express South China E-commerce Warehouse: Deployed an intelligent case packing line for irregular parcels from Shuangcheng Intelligence. Using visual recognition technology to automatically match carton sizes, it processes tens of thousands of parcels daily, efficiently addressing the high-volume and irregular-parcel packing needs in e-commerce logistics.

To help us prepare the most targeted preliminary proposal, please provide:

1. Samples or precise dimension ranges of your current shipping cases.

2. The model and approximate cycle rate of your upstream case packing equipment.

3. The current configuration and challenges of your manual sealing station(s).

You will receive:

• A detailed "Feasibility and ROI Report for End-of-Line Automation Upgrade".

• An online session to view live operation of equipment in a similar application.

• A clear Return on Investment analysis model based on your specific data.

Let's collaborate to transform the "manual island" at the end of your production line into an efficient, flowing "automation hub," and step together into the smart future of Industry 4.0.