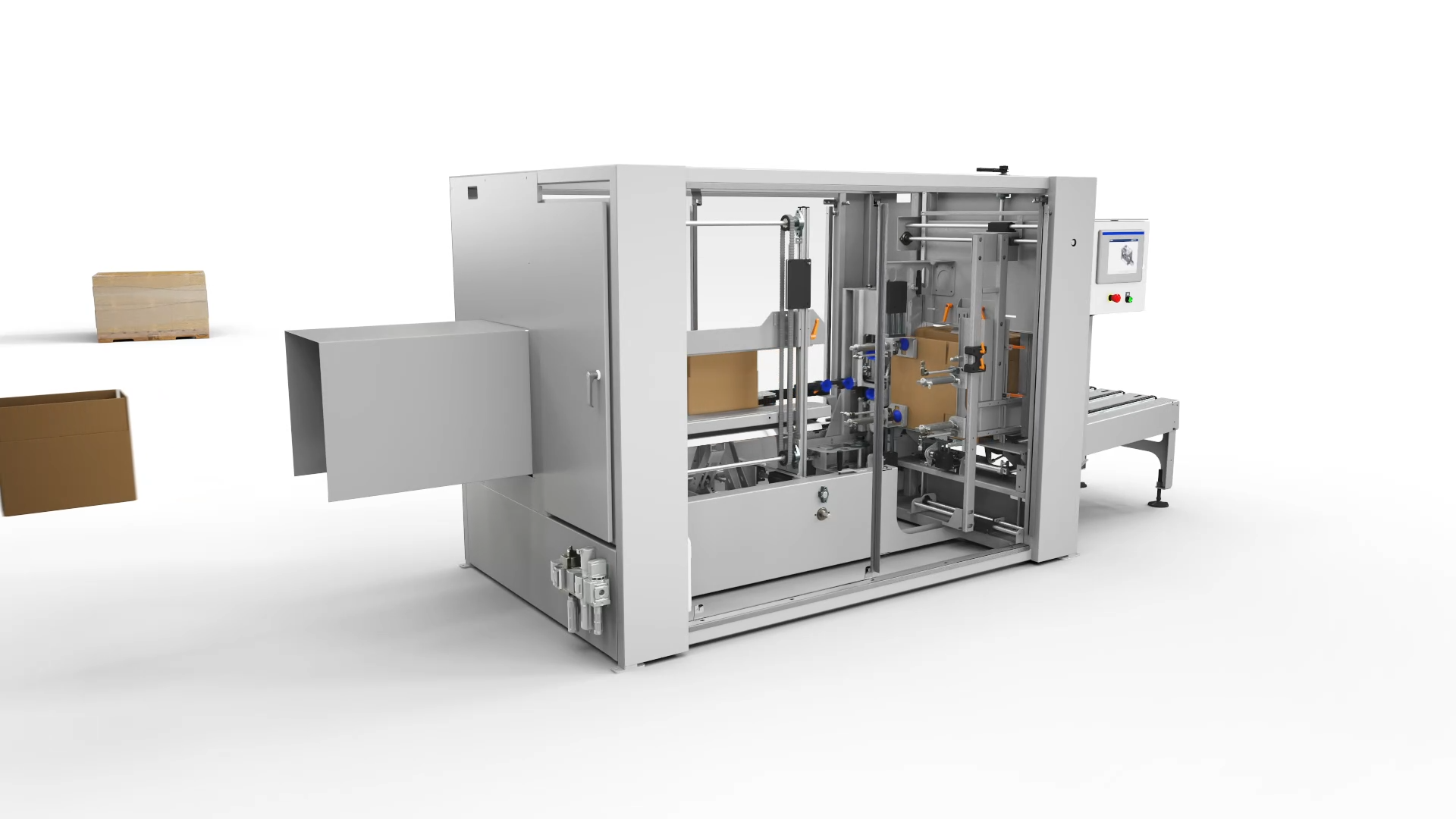

The automatic case erector is an integrated automated equipment integrating carton suction, forming, bottom folding and sealing. Controlled by PLC + touch screen, it is easy to operate, delivering a stable output of 12-30 cartons per minute with a forming success rate exceeding 99%. Compatible with cartons of 80-350mm in multiple specifications, it supports quick mold change and seamless connection to warehouse assembly lines, substantially reducing labor costs and packaging damage rates—an indispensable device for large-scale production.

E-commerce & Logistics: Addresses peak order surges during promotions, supports 8-hour non-stop trouble-free operation, and guarantees fulfillment efficiency with on-site technical support, cutting labor costs by over 72%.

Food, Beverage & Pharmaceuticals: Optional all-stainless steel construction meets hygiene and standardization requirements; features secure sealing to eliminate transportation contamination, and is compatible with recycled cartons for enhanced environmental sustainability.

Electronics & Home Appliances: Precisely controls forming precision to avoid product collision damage, can be integrated with weighing and labeling systems, and adapts to special-shaped and heavy-duty carton requirements.

Small & Medium Manufacturers: Cost-effective models with low initial investment, operable within 30 minutes, and supports quick multi-specification switching—investment payback period within 6 months.

With years of expertise in automated packaging equipment, we are a technology-focused enterprise. Our core products adopt imported components and intelligent control systems, offering strong adaptability and low operation & maintenance costs. We provide customized solutions and 24/7 after-sales response. Whether for mass production or flexible operations, we can accurately match your needs. Welcome to contact us for product selection details and unlock efficient packaging solutions!